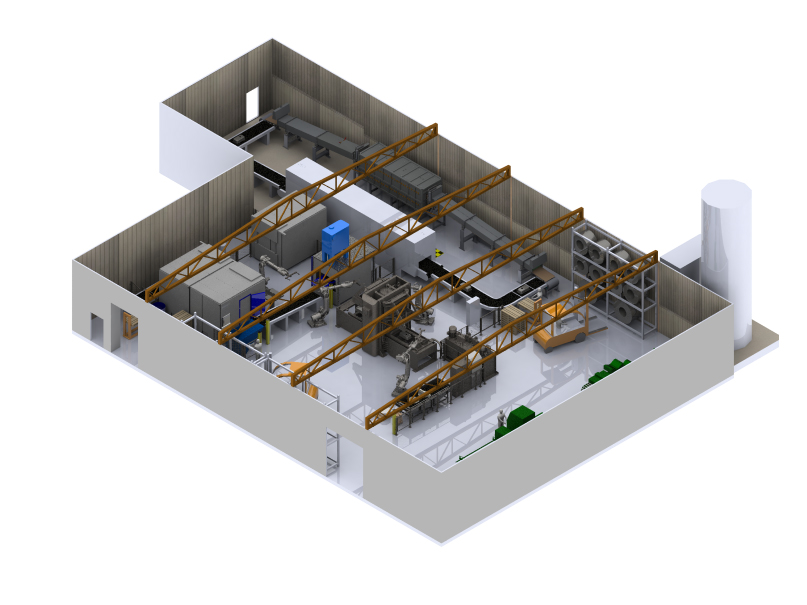

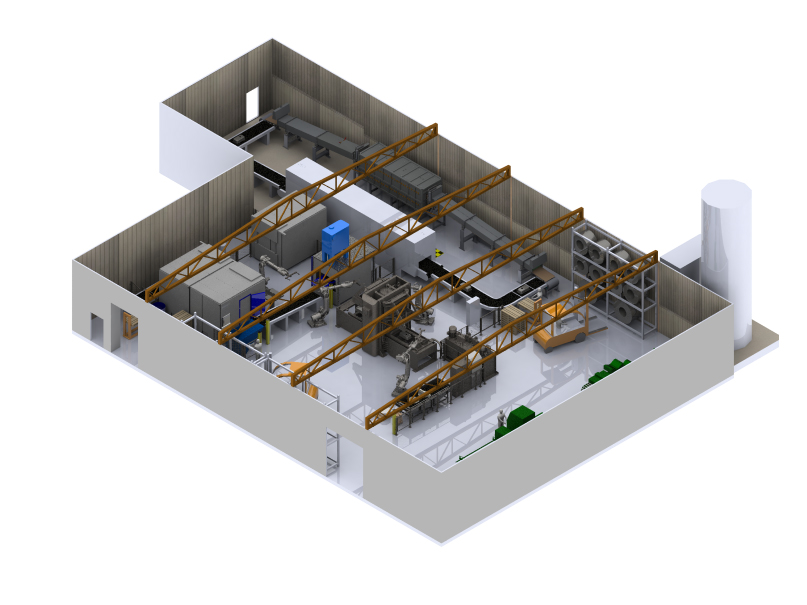

Material processing: Fully automated production line for cutting and polishing of stainless steel

Background:

The customer is a Nordic manufacturer specializing in the high-end kitchen and bathroom equipment with more than 140 years of history in the field of metal products. The company is a Nordic design leader with a minimal product line, fine detailing and high processing requirements. They hope to improve the processing quality and production efficiency of materials through innovative processing techniques in order to increase the proportion of automation applications and reduce labor costs.

Demand

1.Fully automated production

2.Laser cutting to achieve smooth edges without burrs

3.Laser polishing and cleaning, direct finished packaging

4. All processes completed at one time, no need for secondary processing.

Advantages:

1. Stjernberg Laser provides a customized laser cutting system to achieve burr-free and high quality cutting edges

2. Fully automated design, combining the loading and unloading automation with the laser efficient cutting/polishing/stamping process

3. Adopting high-performance dedicated robots to ensure high-precision machining requirements

4. An automated smart production line, with the possibility of running two separate flows

5. Specialized at micro-machining of materials and laser precision cutting with reliable equipment.

Status:

Production status: metal feeding-pressing-cutting-polishing-cleaning-package, which has achieved unmanned production. The production efficiency is greatly improved compared with the traditional process.